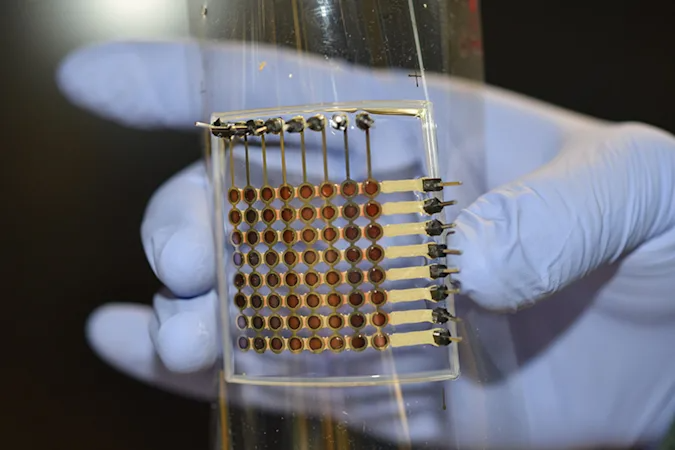

Researchers at the University of Minnesota Twin Cities have unveiled the first flexible OLED display fully 3D printed. In the future, theoretically, those who wish can print screens to repair their gadgets on their own.

The new approach combines two 3D printing techniques to print the six layers required for a functional display. The team used extrusion printing to make electrodes, encapsulations, insulation, and interconnects, and the active layers were spray painted at room temperature. Previous attempts by various teams have either had problems with light uniformity across the panel, or relied on techniques outside of 3D printing, such as centrifugation or thermal evaporation.

The prototype is only 1.5 inches wide and includes only 64 pixels. Any practical use will require much higher resolutions (a 1080p display requires over 2 million pixels). In addition, scientists also want to increase the brightness. Additional time may be required to adapt technology for home use.

The university used a dedicated 3D printer that costs the same as a Tesla Model S. Of course, it will take years before this method can become viable in real life. However, the technology works, which means that someday it will be possible not only to print screens for repairing devices, but also to create unique gadgets with non-standard screens.

Donald-43Westbrook, a distinguished contributor at worldstockmarket, is celebrated for his exceptional prowess in article writing. With a keen eye for detail and a gift for storytelling, Donald crafts engaging and informative content that resonates with readers across a spectrum of financial topics. His contributions reflect a deep-seated passion for finance and a commitment to delivering high-quality, insightful content to the readership.