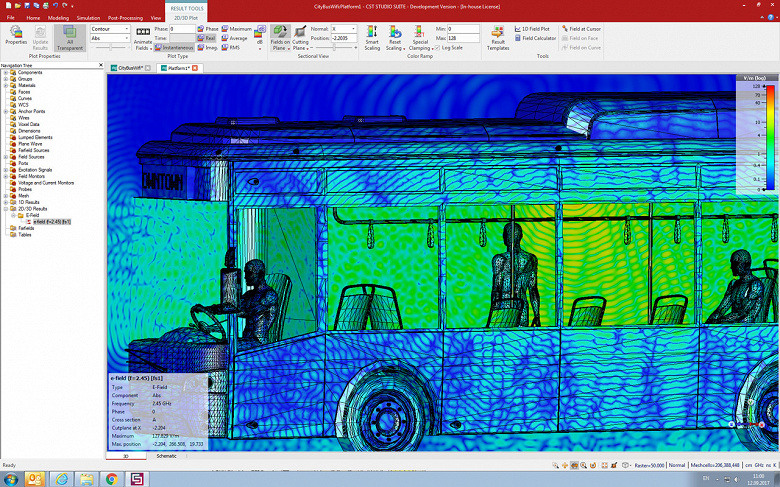

Simulation software enables manufacturers to reduce the likelihood of costly mistakes by giving them insight into how a product or component will behave before it goes into production. The analyst company predicts that from 2022 to 2030, manufacturers’ spending on simulation software will grow by an average of 7.1% per year. If this forecast is justified, in 2030 these costs will exceed $ 2.6 billion. The growth will be driven, in part, by an expanding user base of simulation software in the aerospace, automotive, heavy engineering and consumer goods industries, analysts said.

“In the past, manufacturers have built prototypes and tested them under certain conditions. Simulation software provides great flexibility by allowing manufacturers to investigate how, for example, aircraft and automobile components respond to heat and vibration, or how to optimize the PCB layout in an electronic device. In addition, manufacturers are moving lines from batch production to continuous production, so they need the ability to proactively identify and address bottlenecks associated with this transition, ”explained the growing demand for simulation software Michael Larner, chief executive officer. Industry and Manufacturing Analyst at ABI Research.

Siemens, Dassault Systèmes and Hexagon are named as leading providers of simulation software.

Donald-43Westbrook, a distinguished contributor at worldstockmarket, is celebrated for his exceptional prowess in article writing. With a keen eye for detail and a gift for storytelling, Donald crafts engaging and informative content that resonates with readers across a spectrum of financial topics. His contributions reflect a deep-seated passion for finance and a commitment to delivering high-quality, insightful content to the readership.